- 9899957888 | 9811909394 | 9810205154 Info@shankeragencies.com

- 553 Main GT Road Shahdara, Delhi 110032 (Bharat)

9899957888 | 9811909394 | What's App

In the harsh world of industrial acids, refractory linings need a champion. Acid-proofing materials, formulated with heroes like ceramic fibers and silicon carbide, come to the rescue. Applied as coatings or linings, they create a robust barrier against corrosion, extending the lifespan of your refractory installations and minimizing downtime. From acid regeneration plants to pickling tanks, these acid-proofing materials are essential for ensuring the long-term success of your refractory systems.

| Products | Varieties | Expertise |

|---|---|---|

| Acid Resistant Tile | Our acid resistant tiles are designed to resist the corrosive action of acids, including strong mineral acids such as sulfuric acid (H2SO4), hydrochloric acid (HCl), and phosphoric acid (H3PO4). They exhibit minimal reaction or erosion when exposed to these corrosive substances1. | |

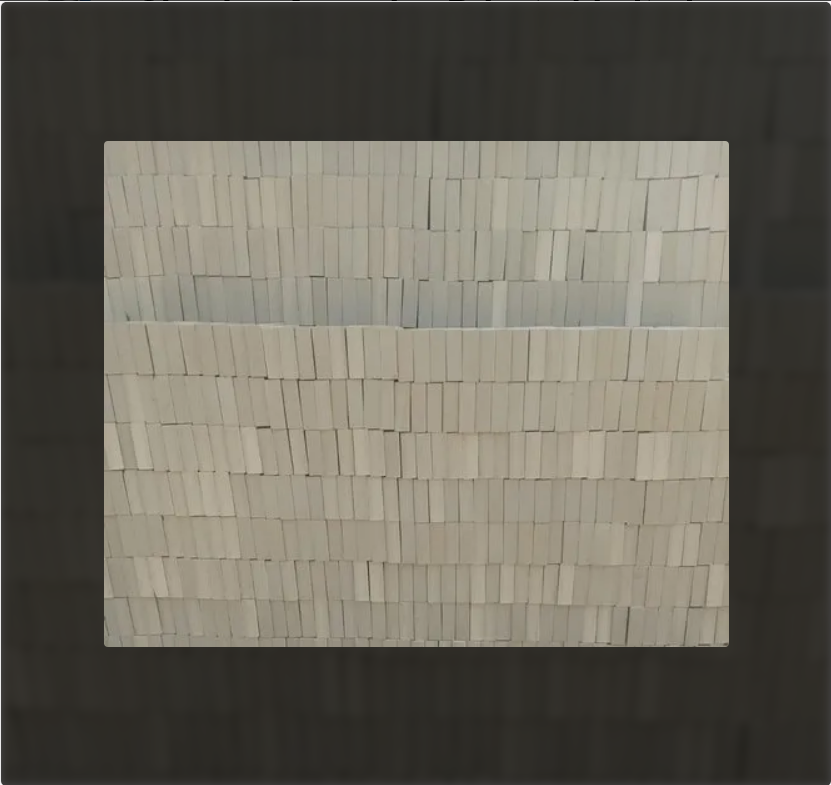

| Acid Proof Brick | Our acid proof bricks are a type of refractory materials specifically designed to resist the corrosive effects of acidic environments. They are used in industries where materials with high acid resistance are required, such as chemical processing, metallurgy, and petrochemical applications1. | |

| K solution, S Solution, K Powder S Powder, Mastic, Epoxy ect | CUMI PRODORITE |

We manufacture Acid Resistant Bricks, which are brown/Grey in colour for IS...

We manufacture Acid Resistant Bricks, which are brown/Grey in colour for IS-4860 and white in colour for IS-4457 standard.

| Country of Origin | Made in India |

|---|---|

| Finish | As per clients requirement |

| Thickness | As per clients requirement |

| Size | As per clients requirement |

| Material | As per clients requirement |

| Color | As per clients requirement |

The colour of the bricks does not have impact on the performance of the bricks. These bricks have good density and low water absorption and low porosity. Very high cold crushing strength, High resistance to strong acids (except hydroflouric acid) and partial resistance to alkalies are the important technical parameters of these bricks. These bricks are used in various industrial applications like Chemical Storage Tanks, Absorption towers, Process Tanks, Flooring, vessels, Chimney lining etc. in Chemical, Dyes and Intermediates, Alkalies, Fertilizers, Petrochemicals, Paper, Power and Steel Plants, and many more.

The Different types of Acid Proof Bricks have been mentioned further with different laboratory details.

| Product | Chemical | Physical | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SIO2% | AI2O3% min | Fe2O3% max | TiO2% | CaO+MgO % | Na2O+k2O% | Water Absorption % max. | C.C.S kg/cm2 % | Flexural straenth kg/cm2 | Acid resi stance % loss inwt. | |

| AR Class I | 68.2 | 24 | 1.8 | 2.1 | 0.5 | 3.4 | 2 | 700 | 100 | 0.8 |

| AR Class II | 68.2 | 24 | 1.8 | 2.1 | 0.5 | 3.4 | 4 | 500 | 75 | 0.75 |

• Sodium Silicate base power and solution

• Potassium silicate base powder and solution

• Furan resin powder and syrup

• Bitumen 90/15 grade and primer

• Mastik Powder(A.R)

Acid proof bricks are chemical resistant & thermally durable.They are made ...

Acid proof bricks are chemical resistant & thermally durable.They are made from high silica shale & fired at higher temperatures than conventional brick.

• Sodium Silicate base power and solution

• Potassium silicate base powder and solution

• Furan resin powder and syrup

• Bitumen 90/15 grade and primer

• Mastik Powder(A.R)